- Test Machinery

- Test Services

- Radial Fatigue Testing

- Cornering Fatigue Testing

- Impact Testing

- Biaxial Fatigue Testing

- Uniformity & Static Imbalance Testing

- Motorcycle Wheel Testing

- Belgium Block Testing

- Fastener Testing

- Deformation Testing

- Trim Testing

- Stiffness/Modal Testing

- Strain Gauge and Data Acquisition

- Videography/Photography

- Composite Wheel Testing

- Environmental Testing

- Calibration & Machine Maintenance

- Wheel Forensics

- Store

Control Systems:

Easy to use control system interfaces are now completely touch screen controlled and run on modern computers with user replaceable parts. Graphing and logging of data provides the ability to visualize the testing underway and investigate earlier portions of the test. Allen Bradley comprises the main components of the electrical system. Umbilical connectors between the control system and machine make moves easy and less prone to startup problems. Built-in calibration routines keep track of dates for all sensors.

Retrofit of Controls:

Our latest control system upgrades can bring life back to old tired equipment on your lab floor. Many test machines produced in the last 20-30 years experience downtime due to dated controls with parts that are difficult or impossible to find. Many machines are in good enough condition mechanically and can be maintained in the plant. These machines may be candidates for control retrofits. A control retrofit gives the benefits of a modern control system without having to take a machine down for a longer period of time and some retrofits can be performed on site.

If mechanical issues like load application, bearings, repeatable results, etc. are a problem, then a rebuild may be a better option. A rebuild makes use of the good iron and provides the value of a brand new machine at a reduced cost. See Test Machinery for more information on a full machine rebuild. Component upgrades are worked into the rebuild process while parts are accessible so they are often done at the same time.

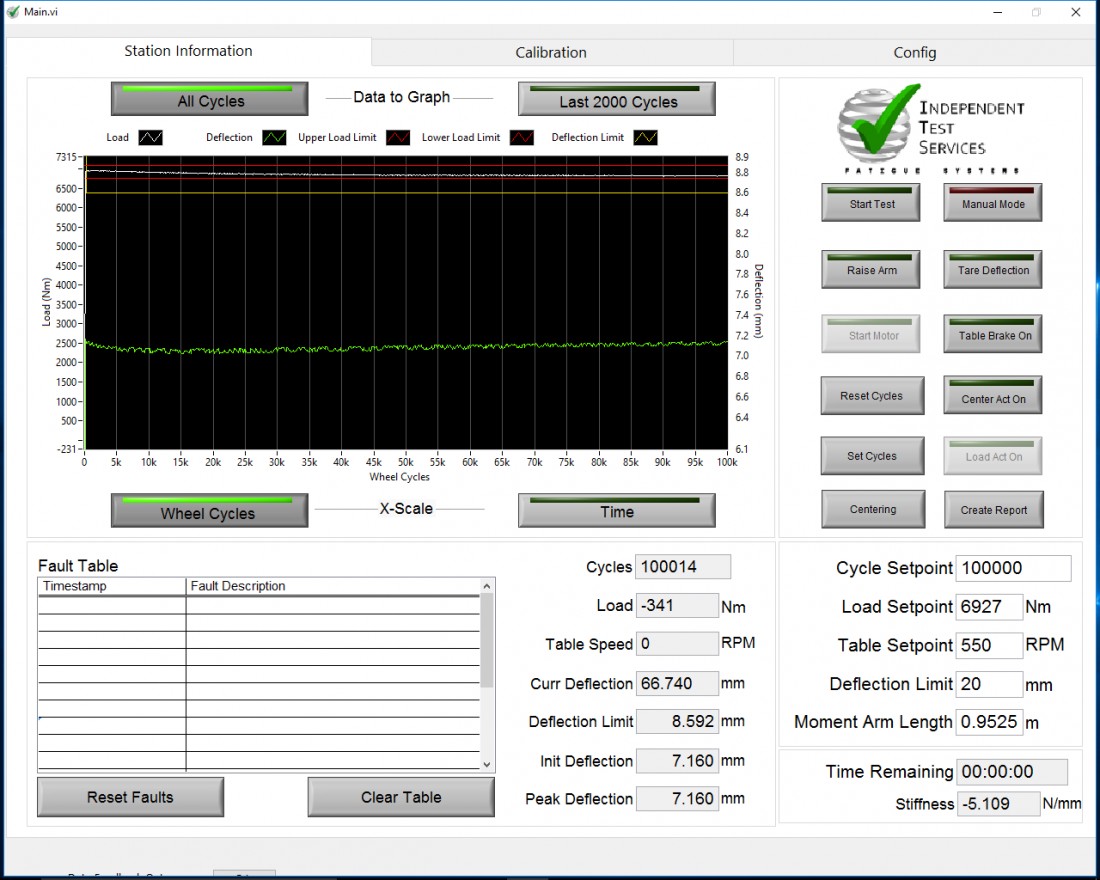

Operating Screen:

Operating Screen:

The operating screen provides a side by side view of the set points and running values which gives the user a visual and digital comparison to work with when setting up the test. A real-time populated graph gives a technician an easy to understand visual of what is happening with the test.

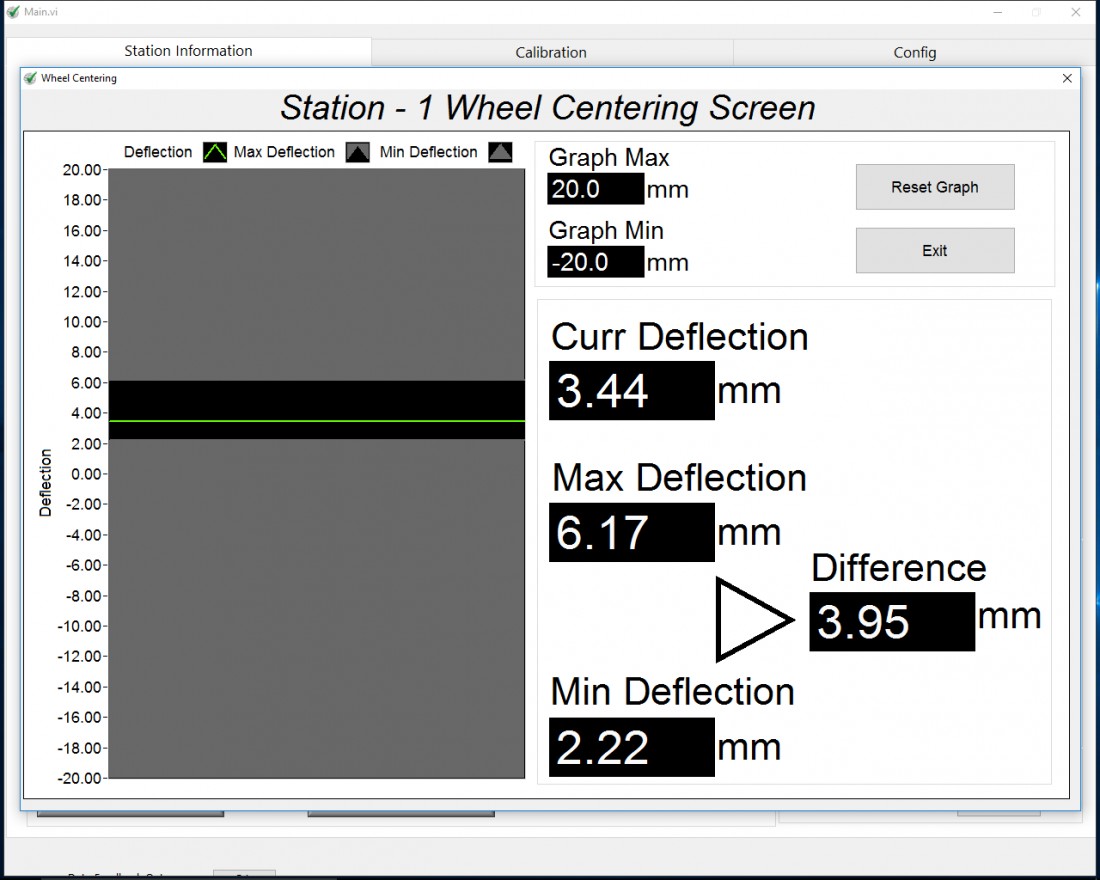

Centering Screen:

Centering Screen:

The centering screen provides a visual and numerical value for the user to use as a guide to make setup more efficient.

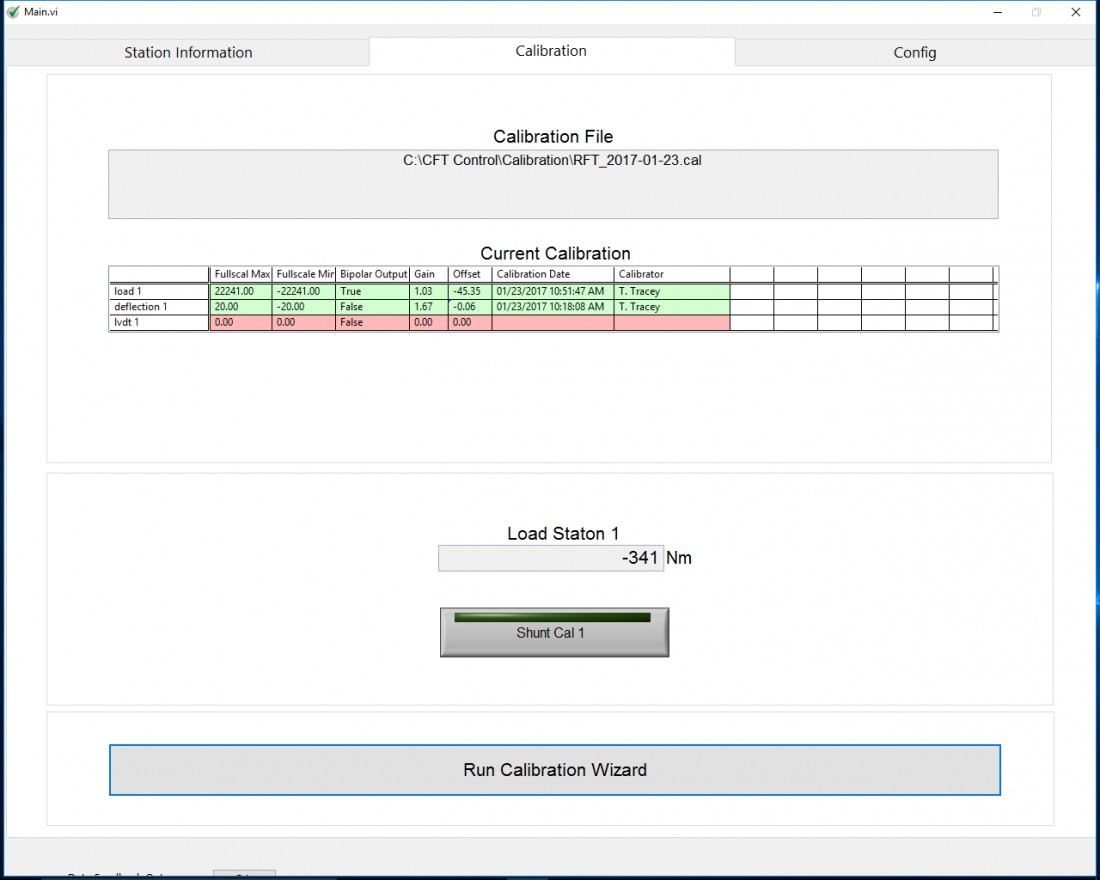

Calibration Wizard:

Calibration Wizard:

A guided calibration wizard walks the user through the steps of a load cell calibration. When readings don’t come in during calibration the field is highlighted in red to alert the user of an issue.

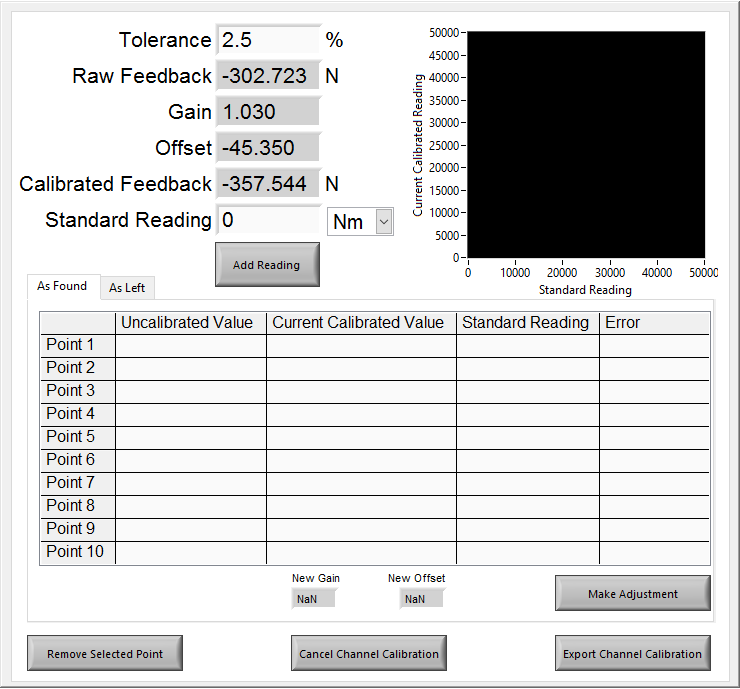

Calibration Setpoint Screen:

Calibration Setpoint Screen:

We can run a 10-point calibration within the machine’s testing range. As you get to each point the readings are added and the system, using an algorithm, calculates the new gain and offset.