- Test Machinery

- Test Services

- Radial Fatigue Testing

- Cornering Fatigue Testing

- Impact Testing

- Biaxial Fatigue Testing

- Uniformity & Static Imbalance Testing

- Motorcycle Wheel Testing

- Belgium Block Testing

- Fastener Testing

- Deformation Testing

- Trim Testing

- Stiffness/Modal Testing

- Strain Gauge and Data Acquisition

- Videography/Photography

- Composite Wheel Testing

- Environmental Testing

- Calibration & Machine Maintenance

- Wheel Forensics

“When you want to know how things really work, study them when they’re coming apart”

-William Gibson

ITS Technology:

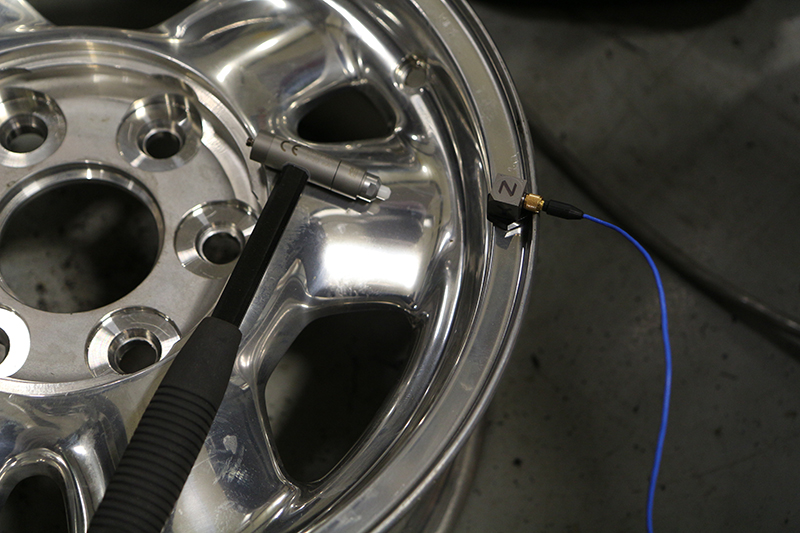

When it comes to technology, ITS has found a way to incorporate the latest and greatest into our testing capabilities. Strain gage application and data acquisition can be done in-house which allows for more customization and faster turnaround time.

When it comes to technology, ITS has found a way to incorporate the latest and greatest into our testing capabilities. Strain gage application and data acquisition can be done in-house which allows for more customization and faster turnaround time.

Data acquisition is done either wirelessly or through a slip ring. Channel count for wireless is currently 4, slip ring channel count is 8 simultaneous channels. Measurement speed of the DAQ equipment is up to 50kS/s per channel allowing for high-speed acquisition on faster equipment as well as impact testing.

Strain data can be recorded on all ITS equipment

- Radial, Cornering, Torsion (4 channel Wireless/ 8 channel Slip-ring)

- Biaxial fatigue (8-12 channels slip ring)

- Impact (8 channel slip ring)

Data can be provided digitally shortly after recording. Data acquisition software accepts strain gage characteristics and automatically calculates span-point for gage calibration process. Data output is in micro-strain. Strain on Biaxial fatigue currently records with actual actuator loads so that stress versus load is easily compared.

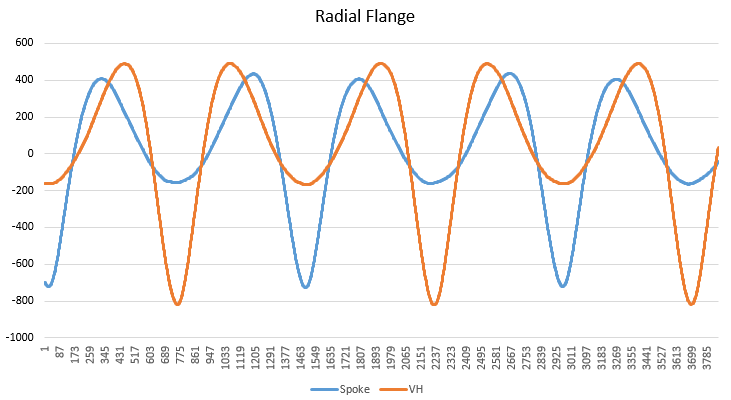

Sample data from inboard flange on radial

High-speed video up to 1000fps and 4 angles can be used to better understand test phenomena. We have light banks and rigging to capture all sides of a test.

With light banks and specialized rigging, we excel at finding ways to get the footage that either explains a test or answers questions.