- Test Machinery

- Test Services

- Radial Fatigue Testing

- Cornering Fatigue Testing

- Impact Testing

- Biaxial Fatigue Testing

- Uniformity & Static Imbalance Testing

- Motorcycle Wheel Testing

- Belgium Block Testing

- Fastener Testing

- Deformation Testing

- Trim Testing

- Stiffness/Modal Testing

- Strain Gauge and Data Acquisition

- Videography/Photography

- Composite Wheel Testing

- Environmental Testing

- Calibration & Machine Maintenance

- Wheel Forensics

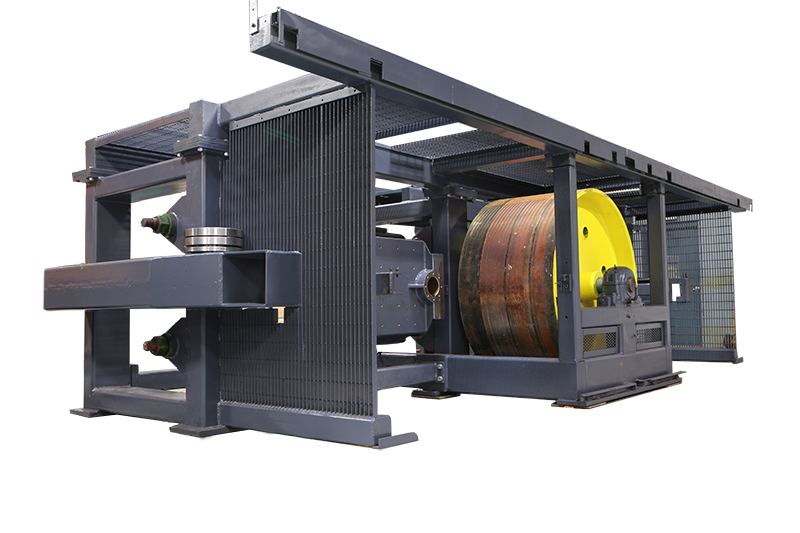

ITS has been operating, servicing and calibrating wheel test equipment for over 20 years and learning the nuances of heavy-duty machinery every step of the way. We rebuilt our first 4-station radial fatigue machine in 2000, upgrading control systems, manufacturing new guarding and spindles, and replacing all of the wearable parts. Rebuilds have become our specialty as many wheel test machines made in the last 20-30 years were built with good iron and can be upgraded with new controls. It’s easier to replace wearable parts and upgrade with more efficient motors. A rebuild that makes use of the good iron provides the value of a brand-new machine at a reduced cost. Along the way, we saw ways the machine design could be improved and started manufacturing equipment from scratch. ITS now handles machine builds from design to runoff. Being a test lab as well allows us to tailor our equipment and upgrades to the needs of a test lab. Setting up and running a test has never been easier.

Radial Fatigue:

ITS has developed an upgrade for the Goal radial fatigue machines that involves removing all of the pneumatic components and replacing them with electric linear actuators. Servo drives replace valves and the electric actuator replaces the large air cylinders. Under test, fine control of load is possible and linear position output is recorded in the graph. When load is achieved, positive brake turns on and actuators do not consume power. Inefficient inductive motors are replaced with high-efficiency AC motors and variable frequency drives.

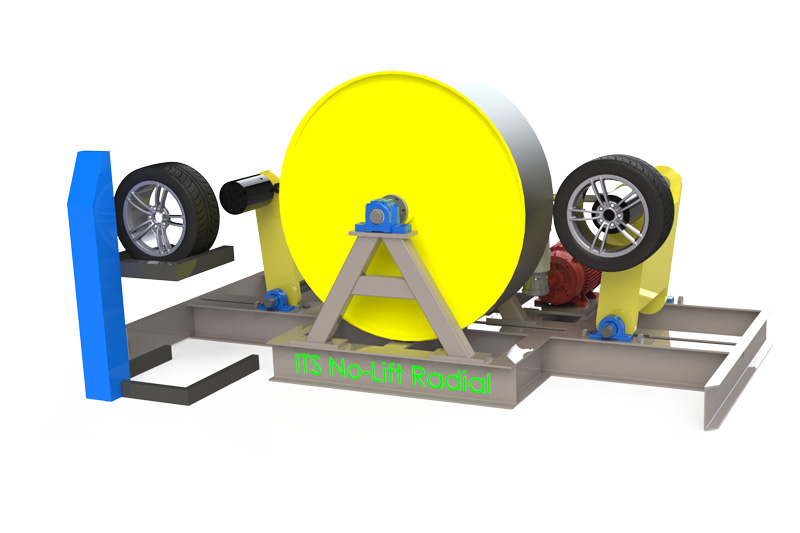

As part of our upgrade capabilities, we have recently commissioned a No-Lift Radial Fatigue Machine that is capable of working with a portable wheel lift to allow an operator to safely install or remove a wheel without having to lift test samples. Instances of fastener misalignment during installation are also reduced. Graphing and recording of tire pressure during testing is available on radial machines via wireless TPMS caps.

As part of our upgrade capabilities, we have recently commissioned a No-Lift Radial Fatigue Machine that is capable of working with a portable wheel lift to allow an operator to safely install or remove a wheel without having to lift test samples. Instances of fastener misalignment during installation are also reduced. Graphing and recording of tire pressure during testing is available on radial machines via wireless TPMS caps.

Cornering Fatigue:

In a typical rebuild/upgrade a full rebuild of the mechanicals consists of complete disassembly, cleaning, sandblasting and repainting. The parts to be reused are verified, wearable parts replaced and then the machine is reassembled. Components are worked into the process so that it can be done correctly while parts are accessible. The rebuild process is often done in conjunction with a control upgrade.

In a typical rebuild/upgrade a full rebuild of the mechanicals consists of complete disassembly, cleaning, sandblasting and repainting. The parts to be reused are verified, wearable parts replaced and then the machine is reassembled. Components are worked into the process so that it can be done correctly while parts are accessible. The rebuild process is often done in conjunction with a control upgrade.

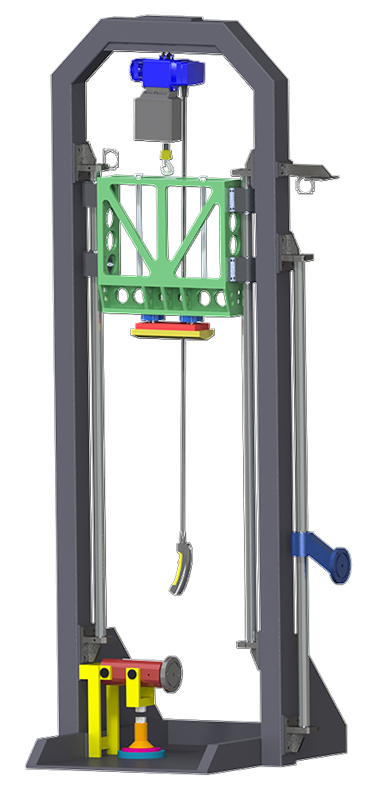

AKR Impact Testing:

ITS now has an impact machine capable of AKR impact testing levels 1-3. The machine is capable of recording inboard and outboard impact forces, deflection and velocity. The machine is also used as an all-purpose impactor for tire testing, JASO impact testing, pre-damage testing and developmental as well as cap testing.

ITS now has an impact machine capable of AKR impact testing levels 1-3. The machine is capable of recording inboard and outboard impact forces, deflection and velocity. The machine is also used as an all-purpose impactor for tire testing, JASO impact testing, pre-damage testing and developmental as well as cap testing.